Setting Up A Preventive Maintenance Plan Key Factors To Consider Tec Option

Setting Up A Preventive Maintenance Plan Key Factors To Consider Tec Option Analyze, correct, improve. it is important to revisit your preventive maintenance plan every couple of years and make adjustments to ensure that it’s the most effective plan for your equipment. continued attention and detailed records of your maintenance plan will make it easier to implement new maintenance plans in the future. A preventive maintenance plan helps minimize future breakdowns and downtime and serves to extend the useful lifetime of machinery. it allows your teams to plan their work better and maintain operational efficiency without unexpected disruptions. a pmp is also important to ensure workplace safety and is often an essential requirement for.

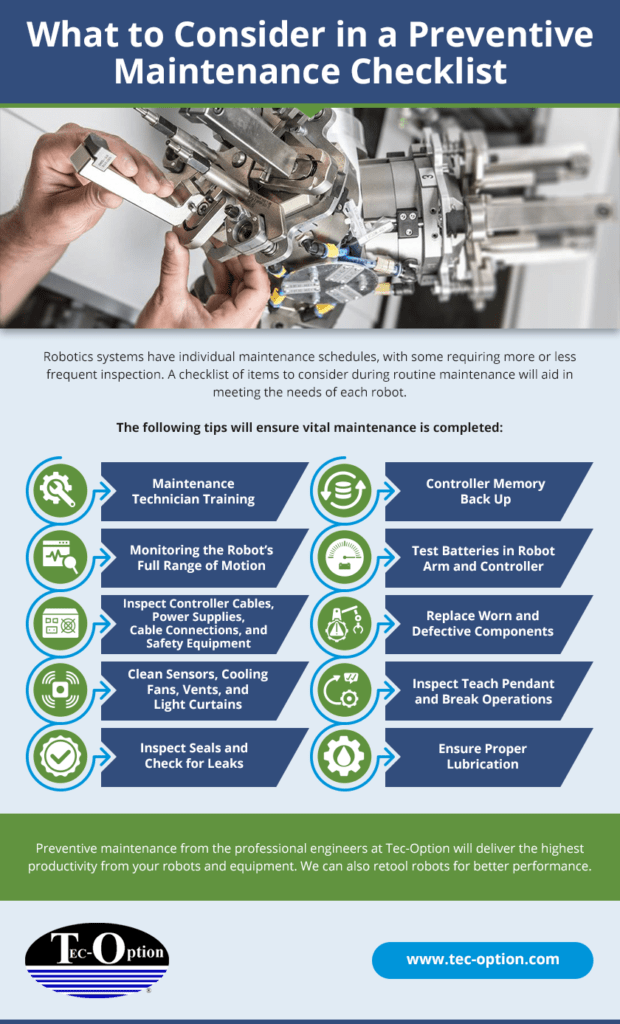

Retooling And Preventive Maintenance Services Tec Option Establish and prioritize goals. create and measure kpis. get stakeholder buy in. use the right technology software. set up pm triggers. train maintenance workers on how to implement the preventive maintenance plan. build a preventive maintenance checklist. fine tune your plan based on results. An effective preventive maintenance program contributes greatly to the overall stability of an operation. these procedures can help maintenance planners prepare a practical system for performing routine maintenance. 1. list equipment and systems. compile a detailed inventory of all critical assets, equipment, and systems that will need regular. Step 1: assessing equipment needs. begin by conducting a detailed inventory of all machinery and equipment. this assessment should include each item’s current condition, maintenance history, and frequency of use. knowing these details helps determine the specific requirements and priorities for each piece of equipment. Step 1: refer to or create an asset list. an effective preventive maintenance plan starts with a good idea of what needs to be maintained. as a first step, create a list of all assets for which you are responsible if one doesn’t already exist. capture key details about each asset such as:.

Designing A Successful Preventive Maintenance Plan Servicechannel Step 1: assessing equipment needs. begin by conducting a detailed inventory of all machinery and equipment. this assessment should include each item’s current condition, maintenance history, and frequency of use. knowing these details helps determine the specific requirements and priorities for each piece of equipment. Step 1: refer to or create an asset list. an effective preventive maintenance plan starts with a good idea of what needs to be maintained. as a first step, create a list of all assets for which you are responsible if one doesn’t already exist. capture key details about each asset such as:. 4. choose your preventive maintenance program kpis. to ensure you can adequately track the progress of your pm plan, transform your goals into concrete targets in the form of kpis. common kpis include mean time to repair (mttr), mean time between failure (mtbf), and overall equipment effectiveness (oee), among others. This lays the foundation for a targeted preventive maintenance strategy. 2. strategic planning and design. next, define preventive and reactive maintenance tasks, schedules, and checklists for each asset. set clear objectives, such as reducing downtime or extending asset life, and create a preventive maintenance plan.

Comments are closed.