Mastering Preventive Maintenance Step By Step Guide To Crafting An Effective Plan

Mastering Preventive Maintenance Step By Step Guide To Crafting An Effective Plan Youtube Discover the essential steps to design a powerful preventive maintenance program in this comprehensive guide, and learn how to garner full support from your. A preventive maintenance plan helps minimize future breakdowns and downtime and serves to extend the useful lifetime of machinery. it allows your teams to plan their work better and maintain operational efficiency without unexpected disruptions. a pmp is also important to ensure workplace safety and is often an essential requirement for.

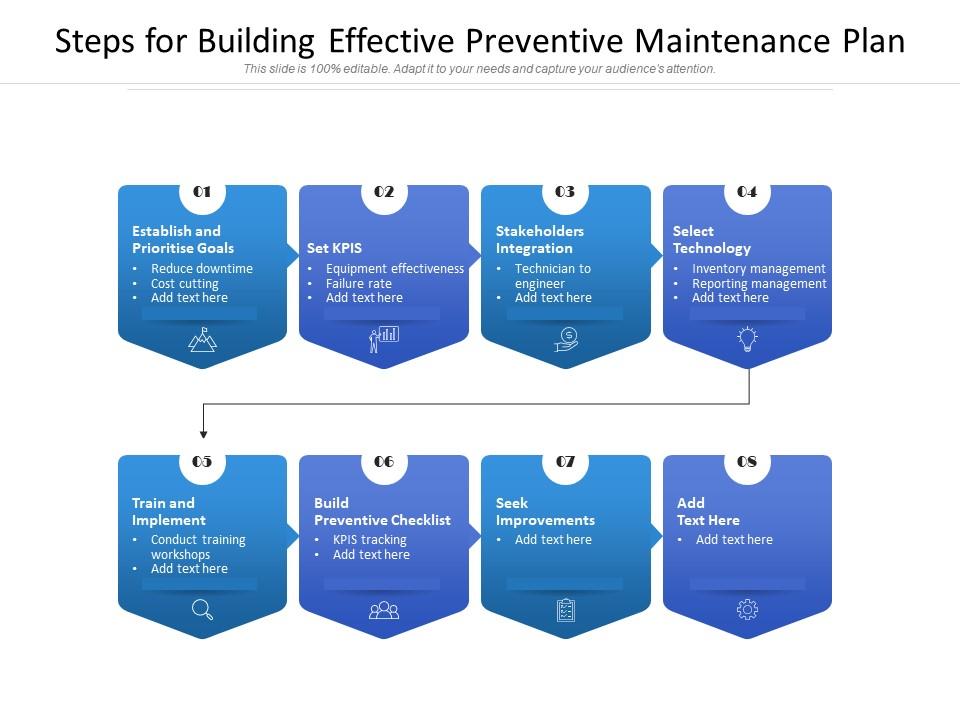

Steps For Building Effective Preventive Maintenance Plan Presentation Graphics Presentation With this in mind, below we present six simple steps to creating your preventive maintenance plan. 1. set priority goals. every organisation has its own priorities and goals when it comes to repairs and maintenance. however, you should seriously think about these in depth so that you can clearly identify your organisational goals. Step by step guide to preventive maintenance. to build a clear, to the point, and comprehensive suite of preventive maintenance checklist, consider these seven critical elements: 1. identify key equipment: start by listing all assets requiring regular maintenance. include equipment name, model, and location to avoid confusion. By shifting from reactive approaches to preventive maintenance, businesses can mitigate the risk of unexpected failures and optimise asset performance. in this blog, we’ll explore a comprehensive five step guide to help organisations navigate this transformative shift effectively. Step 1: refer to or create an asset list. an effective preventive maintenance plan starts with a good idea of what needs to be maintained. as a first step, create a list of all assets for which you are responsible if one doesn’t already exist. capture key details about each asset such as:.

Comments are closed.